Unlike systems that stitch together conveyors and platforms, the Revolution is a purpose-built sorting machine. Designed for sorting, the Revolution incorporates the latest in LEAN thinking. Multi-pass capability provides staffing flexibility without sacrificing yield. One-Touch sorting means that once sorted, material is ready for the truck. The Integrated control system allows your team to focus on the task and let the system work for them.

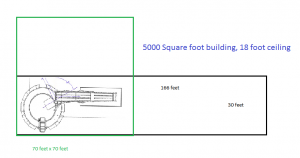

With a compact design, the system can fit into an existing building, just right for starting a new program or upgrading an existing one. On top of all of that, as your program grows and your needs change, you can be easily upgrade the system.

Features and Benefits:

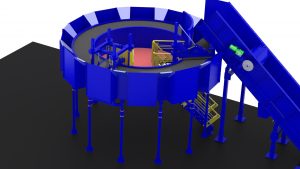

Variable Speed Revolving Sort Table:

This enables “Multi-pass One Touch” sorting. Your operation can scale up or down, depending on how much material you recover. New or experienced crew can find a productive and safe sorting pace without sacrificing yields or requiring additional handling.

Circular Shape:

This results in a small footprint and efficient material flow so that you can use an existing industrial building or warehouse. 60 foot conveyor length/48 inch width equivalent.

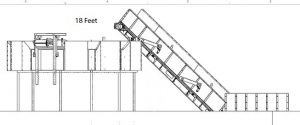

Variable Speed Feed Conveyor:

Provides additional control of the sorting rate and material depth while accommodating varying mixes of material.

Exit Brush:

Can be raised or lowered to enable Multi-Pass capability and clear debris.

Integrated control system:

Integrated control system:

Allows complete control of conveyor, brush, sorting and auxiliary equipment from a central location on deck. All workstations include an integrated “E-stop” control.

10 Stations: Provide for recovery of up to 11 separate commodities.

“Multi-pass One Touch:”

Vertical or horizontal balers capture high volume material directly without additional handling or movement. Bins and transfer conveyors handle lower volume material.

Small Footprint:

Minimizes material travel distance, saving operator time. This also allows you to use a pre-existing building to keep project costs low and locate the facility nearest the need. Only 5000-6500 square feet with 18 feet of clearance are needed to get your program moving.

“Tall Enough”:

Available in multiple heights, the Revolution© can be placed where other systems can’t go.

Simple Design:

Keeps power requirements low, further reducing your building costs while keeping electricity costs down.

People first:

We focus on minimizing non-value added steps like movement and handling. We concentrate on optimizing the sorting step and facilitating teamwork. This results in higher productivity AND high sort quality compared to other systems.

The Bottom Line:

Creating a social environment that facilitates and rewards teamwork improves productivity. Minimizing movement saves space – which saves on building costs while reducing non-value added work. As a result, the Revolution excels in a broad variety of sorting applications, including those listed here.

See our detailed specifications here.

See it in action here.

Want to take a tour? Contact us