We Listened

A product, not a project

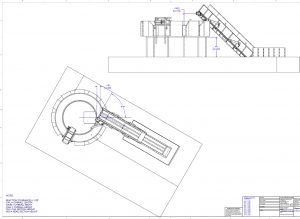

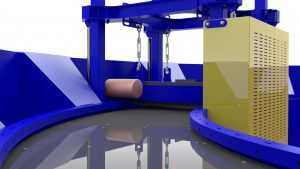

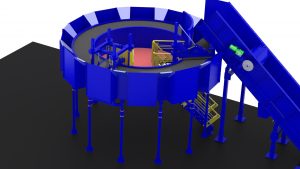

Purpose Built Sorting System

Unlike other systems that stitch together conveyors with a platform, the Revolution is a purpose-built machine, designed with your needs in mind. Multi-pass capability provides staffing flexibility without sacrificing yield. One-Touch sorting means that once it’s sorted, it’s ready for the truck. The Integrated control system (feed rates, brushes, balers auxiliary equipment) allows your team to focus on the task and let the system work for them.

At Home Anywhere

The compact system can fit into a 5000-square foot building with 18 feet of overhead. This saves space and the expense of a new building – just right for starting a program or upgrading an existing one. On top of all of that, the system can be easily upgraded as your program grows and your needs change.

The most productive machine on the market

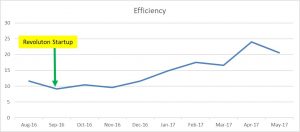

Our simple, focused approach pays off in results for our customers. With centralized control on deck, teams can adjust feed rates, material depth, belt speed and debris removal to optimize their performance. Working together on the platform, the sort team can flex and support each other as the mix of material changes. If members shift to baling need to take a break, the team adjusts dynamically. The result is steady continuous improvement in performance. The bottom line: lower processing costs and more sustainable programs. This means jobs for people, profit for businesses and a healthier environment for the community.

The power of people

Automation has its drawbacks and comes with hidden costs. Besides the high up-front costs, sort automation systems can bring low material quality and contamination. By keeping an operator in the loop, we are able to maintain higher material quality and lower contamination rates (higher prices) than traditionally automated systems. Our one-touch approach allows us to minimize non-value added steps like movement and handling (baling) while optimizing the value added step of sorting. Minimizing movement and handling reduces the need for and the cost of automating those steps and increases the productivity of the team. As a result, your return on the investments you do make in automation increases.

Automation has its drawbacks and comes with hidden costs. Besides the high up-front costs, sort automation systems can bring low material quality and contamination. By keeping an operator in the loop, we are able to maintain higher material quality and lower contamination rates (higher prices) than traditionally automated systems. Our one-touch approach allows us to minimize non-value added steps like movement and handling (baling) while optimizing the value added step of sorting. Minimizing movement and handling reduces the need for and the cost of automating those steps and increases the productivity of the team. As a result, your return on the investments you do make in automation increases.

The Revolution© is a turn-key system that costs less than the competition while delivering better material at twice the productivity. It can be configured to match the needs of your current program and upgraded as your needs evolve. Curious? See more, contact us or request a quote to to see how a to start a Revolution© in your community - or check out this case study.