Problem

No matter how small the plant, some tasks don’t simply go away. Others require training or expertise to accomplish properly: payroll management, production reporting, inventory management, tracking shipments, managing sales, managing supply and tracking operational efficiency. Traditionally, plants have dedicated resources for purchasing, HR, supply chain, manufacturing management, inside sales, logistics, scheduling and machine maintenance. All these responsibilities are overwhelming for a single person. Can you afford someone with all these skills? Can your business accept errors in any of these business areas?

Solution

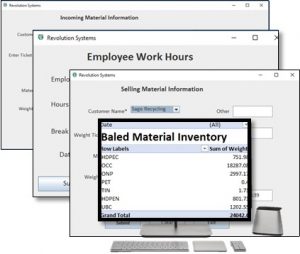

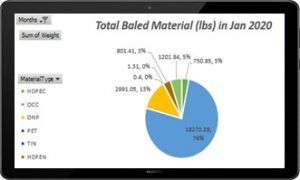

Revolution Systems has developed “Simple In$ite”, a cloud-based solution to automate common tedious tasks including order entry, payroll, accounting, invoicing, reporting and more to manage the plant efficiently. This solution rules out the need for expensive ERP (Enterprise Resource Planning) software and supports the plant manager. Automation cuts down many hours of administrative work, and allows the plant manager to focus on more important assignments. Simple In$ite delivers a complete suite of reporting tools, providing an interface that is easy to learn and reduces human error. The application includes a customizable dashboard and other tools that show inventory status, MRF efficiency, manpower productivity, clean or dirty incoming material with a residue level. Simple In$ite provides a real-time and remote solution to track the productivity of the plant from anywhere and at anytime. Data gathered can be imported into other processes that will drive payroll and invoicing. It also provides real time inventory data to brokers and processing plants, and transportation teams to streamline outbound logistics. This increases efficiency on an organizational scale, ensures smooth operations, and improves productivity.

Features and Benefits:

Production Reporting

Provides an intuitive platform to collect, monitor, analyze and control operations, eliminating the need for spreadsheets and paper reports.

Payroll

Time clock functionality. Tracks hours of employees for payroll and productivity measurement.

Inventory Management

Tracks incoming material, finished bales and shipments. Information may be shared with brokers, mills and transportation companies to expedite to end markets.

Invoicing

Collected inbound and outbound material data may be fed into invoicing systems.

Notification Services

Provides email and text notifications to designated internal and external recipients of certain events: 1) Inventory limits, 2) Machine breakdown, 3) High residue rates.

System Performance

Tracks system downtime of the Revolution System and its components.

Interactive Dashboard

Real-time, top level view of plant performance with access to details and trends for each category: hours worked, material processed, inventory, shipments, contamination and contaminants. May be accessed anytime from anywhere in the world.

Multi-Site Management

Manage multiple locations remotely and receive real-time status of all the plants.

Simple In$ite helps the MRF site manager with administrative data, reducing the time spent on tedious work. Simple In$ite collects the data needed for management decisions, focusing the site manager on efficient operations. The reports provided by Simple In$ite include machine status, productivity, inventory levels, residue rate and hours worked accessible from anywhere and at anytime.